Hi I will be starting an electric guitar project once I get my fob next week

initial thoughts on specs:

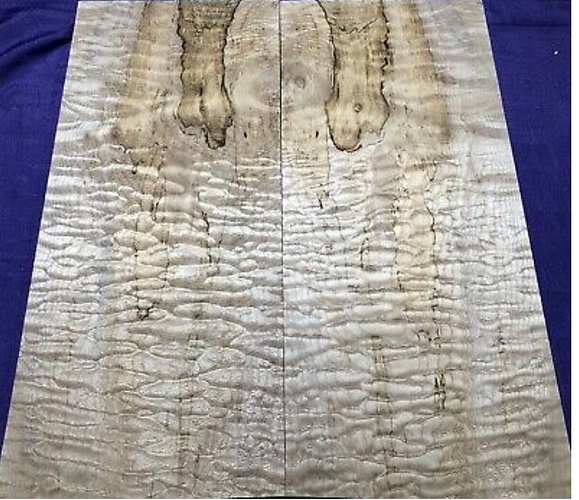

Swamp ash body with spalted maple top with white binding

Curly maple neck

Ebony fretboard

Stainless steel frets

Dual action truss rod (accessible from the heel)