Hi @metaltechs I am thinking of making a tap follower for my next project on the metal lathe, after @stefanoromano made a comment that we don’t have one but I could make one.

Seems like it ups the complexity from what I have made so far in a few different ways, but I have been thinking it through and throwing together some designs in fusion. I have some questions before I jump headfirst into it though, primarily because I want to better understand the mechanics in play while tapping.

First things first, it seems like it might be a better idea to make it out of mild steel, but so far I have only worked with aluminium and brass. What do I need to learn/be aware of before I can work with steel? perhaps I could make a prototype from aluminium?

secondly, it should be reliably concentric with the tailstock, which as I understand it, requires a morse taper. I think I know how to cut a morse taper if I am able to offset the tailstock and turn a taper between centres, or using an angled compound if I want to make a smaller taper. I also don’t know the specific dimensions of the taper on our lathe (I think it’s a MT 3 based on the specs in the manual, but we also have morse taper sleeves I can use, and I don’t know the best dimensions to use there.)

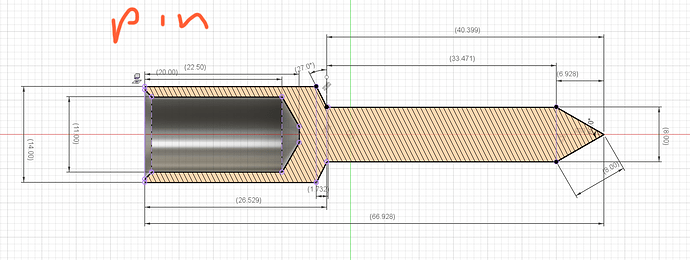

Thirdly, more a sanity check over my general design:

I think if I am adding a taper, I would add a lip/flange to the green tinted plug section on the right, so the spring would be pushing directly off of the tailstock rather than putting pressure on the screw that keeps the outer barrel on it (the barrel and screw would only be under a little tension while the spring is at maximum extension and not while the whole thing is under load while tapping). I have an extended sheath around the spring as part of the pin, intended to keep the spring straight, and stop it catching, but also to provide a smooth, linear travel as it is supported by a slip fit on the outer barrel.

I considered using a thread to keep the back plug on and provide pre-load to the spring, however this could potentially result in it becoming unscrewed while the tap rotates on the other end (rotational forces could be transferred through the spring) so I settled on drilling and tapping a hole for a screw to hold it in place.

On a couple of these parts - mainly the barrel face and the pin point, it seems like it would require me to remove it from the chuck and rotate it 180 degrees, but this would break concentricity. I can fix that with a few techniques, but I would be interested in knowing the best methods.