A 19 mm shank for a tap follower would be a very chunky monkey – not sure how many 30+ mm internal threads we intend to tap by hand (gym bunny anyone?) or how many machines we have that it would work for - another great reason to ditch the Morse Taper – think pillar drill.

Rotational forces are negligible, as this is a hand tool and not subject to powered rotation, so it probably doesn’t need to be designed out – particularly if the screw cap is at the back. The pointy bit has to be a clearance fit, so it will rotate on its own, unless the spring is a “hella-supa-forceful-boingy” or you decide to somehow key it in position, which, although totally unnecessary, would make for a lot of fun trying to screw up.

The actual forces that need mitigating are the twisting and cocking forces generated by those of us with gorilla hands that can’t turn a true twisting motion on the tap handles – most of us… (it’s the primary purpose and the need for the tap follower in the first instance). Ultimately, this tool will live and die as much by the quality of the machining as opposed to the bells and whistles in the design. Also bear in mind that once the tap is properly engaged, it’s self-centring, after which the tap follower simply sits there as toolery (tool jewellery).

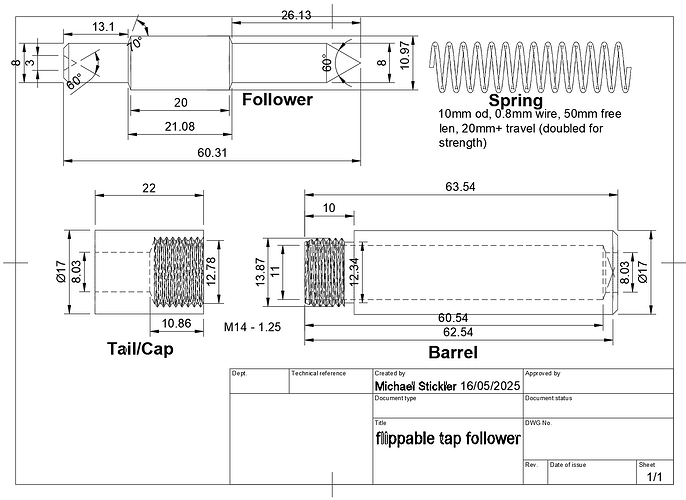

Final thought for ya… Not all taps have a machine centre for the ‘pointy bit’… Smaller taps are pointy, meaning the ‘pointy bit’ needs to have a centre or a ‘not pointy bit’, so the small tap’s pointy bit can fit in the ‘not pointy bit’ centre!!! #SeeWhatIDidThere? Maybe the pointy bit needs to be double-ended, or you could have two pointy bits – one pointy, one not – that you can swap out?? ![]()