Hello everyone,

I’m Tom, I’m just up the road in Tulse Hill. I’m mainly interested in wood working but I also dabble in basic coding for home automation and making gizmos with ESPHome

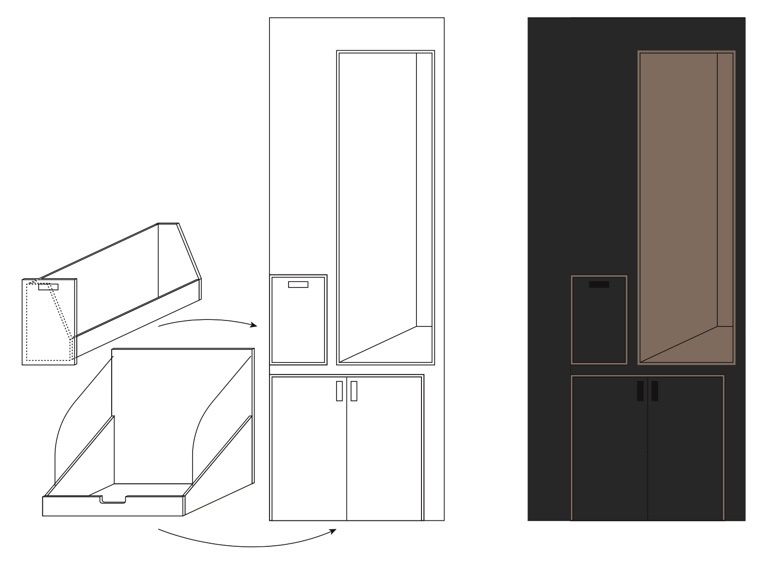

Right now I’m putting together some CNC built in storage I designed:

Unfortunately, one of the drawer bottoms has come out slightly too thick to fit into the rebates in the drawer box.

I’m hoping that somebody might have access to a thickness planer and would be willing to show me how to use it?

The drawer bottom is 558x291mm, the rebates are 8mm.

The drawer bottom seems to be 1/2mm too thick, I have a random orbit sander and have tried that but am concerned that the thickness won’t be consistent if I go down that route. Happy to be advised otherwise, any help or suggestions much appreciated!

Thanks!