@kyle @Christian if you will be around, could you help Hugo setting up the new up down cut tool? Yellow label next to the 3d milling tools…

I forgot to mention this… Looking at your design, you only need 1 toolpath, a profile, for everything… No roughing or finishing

I’m in California unfortunately

It’s not far… Junp on a bus

Archie showed me how to do that when setting up the 3D milling tools.

Any suggestions for cut depth for ply with this new tool?

Won’t 2 toolpaths be needed - not for roughing and finishing, which isn’t needed, but for machine vectors, with first toolpath cutouts with cut being on inside, and second for the main pieces with cut being on outside. Is there a way to swap machine vectors within a single toolpath with vCarve?

Thanks all for the advice. I really appreciate it. I’m planning on heading into the space tomorrow night (Monday). Likely around 8pm. If you’re there it would be good to pick your brains in person, and I can fix the tool path ready to some cutting Friday.

The new tool can have settings as on apt website, but those are just reference and it requires to be adjusted to our cnc.

Regarding the toolpaths… As far as i can see from the picture, only 1 is needed for all the vectors plus a second toolpath for plunging tools for the screws ( actually, in order, the latter first and the profile as second)

If only one toolpath and only one machine vector is used for the profile toolpath, then, as far as I can see, the cut won’t be exactly on the line. If ‘outside’ is used, then the ‘windows’ cut out of the interior of some parts will be outside the line rather than inside. If ‘inside’ is used, those windows will be cut out properly, but the pieces themselves will have a cut 6mm inside the line. How would you make it cut pieces with exactly the same size and shape as those vectors with only one toolpath and a 6mm diameter tool? Am I overlooking something?

Inside and outside is relative to the vector selection. Check when you create the toolpaths and you can see where the cutting will be done

(I’m afraid I’m in the US, too. Potentially could help mid/end of next week if help is still needed.)

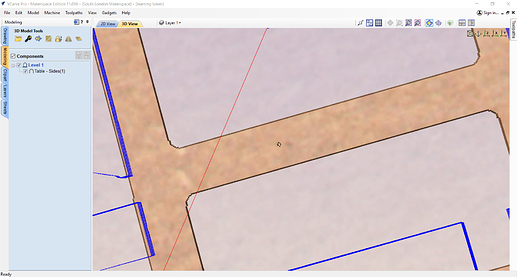

Looks like @Federico is right, a single outside toolpath will do the correct side of the vectors.

New odd problem. During import of an STL into VCarve I get a nice smooth render of the shape complete with 2mm holes. e.g.

However as soon as I’m out of the import screen the render suddenly very low resolution, and missing some of the holes. This of course is then translated into the resulting vectors. e.g.

Because you are importing a 3d model… You need vectors

I’ve found vcarve renders things at fixed resolutions but it doesn’t always reflect reality. I use this free online viewer to spot check gcode: https://ncviewer.com/

But as Federico mentioned, it’s usually a smoother workflow to project lines and use 2D vectors.

Vcarve definitely has some cool 3D tools that can make quick work of certain tasks but I generally reach for Fusion360 for any advanced CAM.

Ok. That makes sense. I’ll see if I can find a way to export my models as SVGs. I’ve been using onshape because I’m cheap and don’t want to pay for licences for things. That might come back to bite me

From fusion you need to export the dxf from the sketches

There is free personal use license of Fusion360. Download the trial, then when that expires you will be able to register for personal use.

Sorry i misread… Then if you can export it as dxf , svg, dwg, pdf or ai it would be fine

I found a way to do it onshape. Create a drawing, layout all the pieces, then I can export as pdf, svg, etc. Everything is a bit more difficult because I’m linux as well

Thanks so much for the help today @dannz

A couple of photos

Surfaces shouldn’t need too much of a clean up:

I might make a few tweaks to the design before cutting the second one.

@CNCtechs I’m feeling a more confident with the CNC, could I get inducted with the big CNC?

Looking good!! Did you use one of the newer Downcutting tools? They should have less tear out on top.

Big cnc induction is no problem. Next time I’m in just grab me or we arrange an appointment.

I’m back in the UK next week and can’t wait to get back to the makerspace.