SAFE WORKING PROCEDURE

Description of activity: Turning wood between centres or on the headstock and for sanding and applying finishes to wood

Induction: Mandatory

PPE: Eye protection compulsory, face shield preferable. Dust mask when sanding. Suitable footwear.

Before

- Tie back or remove loose clothing.

- Tie up long hair.

- Remove jewellery, neckties, gloves etc

- Clear machine bench of any loose items

- Check over lathe and tools for damage

- Check the working area is tidy and there are no trip or slip hazards

- Use appropriate drive and tailstock, faceplate or chuck for the job. Check it is secured in lathe and all locking knuts are tightened. If using a faceplate make sure wood is attached with screws of appropriate length and diameter.

- If tailstock is not needed make sure it is removed from lathe bed.

- Set appropriate speed

- Be aware of the woodstock you are using. Inspect it for defects. Remove any loose bark or knots. Don’t turn anything with metal in it. Check it is within the safe dimensions for the lathe

- Set tool rest at appropriate height and distance from work. Rotate work by hand to check it doesn’t hit the toolrest before switching on.

- Remove any adjusting keys or wrenches from machine before switching it on

- Plan your cuts and make sure you have suffient working space

- If sanding or finishing and toolrest is not needed remove it from lathe bed

During

- Stand to the side when first turning on the lathe

- Listen out for unfamiliar noises - if so turn off the lathe immediately and identify and rectify the problem.

- Keep firm hold and control of the turning tool at all times. Use extreme caution where knots and voids are exposed in the wood

- Always keep tool in full contact with the toolrest when applying to the workpiece

- Keep hands and fingers well away from all moving parts

- Use dust extraction if sanding and be aware that some wood dusts can be highly irritant

- Do not leave machine running unattended

- Use the correct gouges for the task. Don’t use improvised tools

- Do not allow tools to dig into wood.

- Exercise good practice; cut downhill, don’t take excessively heavy cuts, keep the cut supported

- Always use scrapers in trailing mode

- Never stretch over the rotating workpiece, keep tools safely away from immediate work area

- Never adjust the toolrest whilst machine is running

- When sanding/ polishing make sure your hands are positioned so as not to be pulled into the direction of rotation (usually underneath the workpiece)

- Turn lathe off if using callipers to measure work. never touch callipers or other instruments against turning workpiece

After

- Make sure everything is switched off

- Tidy up your working area: brush down the lathe bed, put all tools safely away, tidy area around lathe.

Lathe specs

Name of tool: LATHE (TYME AVON)

Headstock thread: 25mm diameter, 2mm pitch

Tailstock: 2 morse taper

Motor: ¾ Horse power

Speeds: 470, 750, 1150, 2000 rpm

Maximum turning diameters: 275mm (11”) over bed

200mm (8”) over tool rest

500mm (19 1/2”) at 90⁰

580mm (23”) at 180⁰

SPEEDS

The best speed for turning a particular piece depends upon many factors such as its diameter, the soundness of the wood, and whether the piece is balanced. Your comfort level should be considered as well. Therefore, it’s not possible to make a hard and fast rule; the following is only a guide:

Between centres:

Faceplate turning:

If in doubt use a slower speed than you think, particularly if stock is unbalanced. You can always increase the speed once you have roughed it down to a cylinder.

When drilling or boring use an appropriate speed for both the stock and the bit being used.

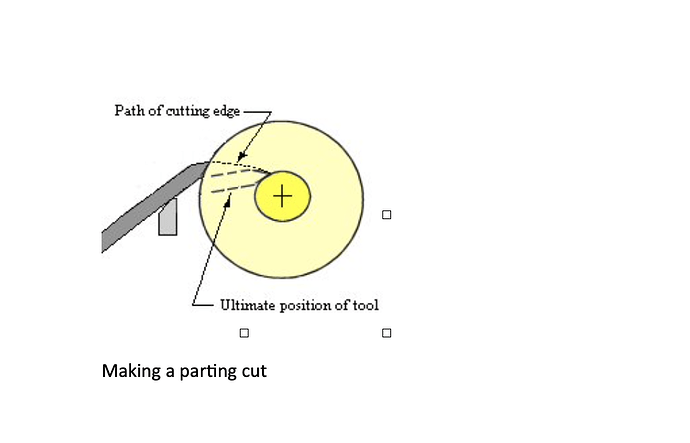

TURNING DIAGRAMS

Check this