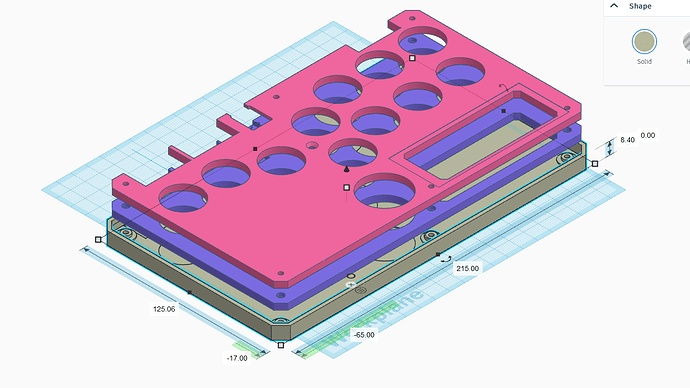

So I’m going to be making a fightstick, and one of the ideas I had was to make it completely transparent minus a potential steel plate at the bottom, with a laser cut plexiglass top plate. The main frame which the PCB will sit on is a 3D object with some small hollows to fit switches:

My original idea was to 3D print this, but making that transparent would be quite tough? What would be the best approach for this? I’ll also have to insert some standoffs for the screws to hold it all together, thus the small corner holes which I thought I could heat up slightly to expand, fit standoff in, then let it cool around it.

Thanks for the help!

Is it just him or do you play as well? I always thought that the acrylic over the top would help block out the UV rays thus preventing yellowing, is this a quirk of the material itself?

Is it just him or do you play as well? I always thought that the acrylic over the top would help block out the UV rays thus preventing yellowing, is this a quirk of the material itself?