I think it will probably need to be raised up for the water tank, which would need to go somewhere…but possibly…

Its worth remembering the laser storage is currently in the space where the CNC is meant to go, so there were recently talks about dismantling this as it was built without members agreeing to this.

Fact is there is no space unallocated in that room, so it’s 2nd laser cutter verses something else and as the only thing we haven’t bought is the CNC it would be the CNC that would have to sacrifice.

@directors I’m super concerned that the problem with this poll is that members don’t really understand what the implications are and what that laser cutter is capable of, and the tone it’s just taken suggests it’s quite divisive.

I will figure out a way to make it work, will need to do some experiments

It has its own extractor fan, so it puts some energy into the system.

As I heard last night there were three options,

- Give it away directly

- Keep it

3 . Flash it , make it a better unit then choose 1or2

@directors given the contention over the poll options I would suggest we invalidate the poll and call another one.

However if we do that I think it would be sensible to make it clear to people that the second laser cutter takes away from the CNC as at the moment this isn’t clear to people, they keep focusing on yes lets have a second laser cutter and not realising this means no space for a CNC.

When I saw it, I was going to criticise having a poll without a re-statement of the case for and against, but then I thought even trying to summarise the arguments would be contentious. So, dunno.

But, to my understanding (or bias) even the pass-it-on camp was pro-flashing it. So let’s do

And choose when it’s a better understood thing.

When is the CNC’s ETA?

Is there an obvious reason I have overlooked in keeping (and flashing it) UNTIL the CNC arrives?

Everyone then knows where they stand.

It’s then offered to another group.

There is no ETA, it’s potentially a pretty expensive piece of kit, though we should probably put some effort into it now.

So we aren’t faced by a binary choice of either 2nd laser unit OR CNC.

If, as it appears, CNC is the majority end goal, we all work towards it.

In the meantime it’s space, in theory, can be used by the 2nd laser unit.

The proviso is 2nd laser advocates understand and agree it will be donated to make way for the CNC.

The only curve ball being if other members want to put forward a case to use the CNCs allocated space, until its arrival.

I think it would be great to have pictures and dimensions. As I understood from the meeting its a a3 table top cutter so very little space( I could have this wrong) I would have thought something could be adusted where we currently store laser supply.

There would still be room for a decent size cnc if the misc table and unkn own items being stored underneath were removed currently next to the laser cutter.

It requires a tank of water for cooling my and a computer to operate it as a minimum.

Main parameters:

420 x 300 mm work areaMachine footprint 930L x 667W x 430mmProfessional Lasercut softwareOperating system Windows XP or aboveCommunication Interface USBCutting depth 0-8mm acrylicEngraving depth 0-1.5mm acrylicEngraving speed 800mm/sCutting Speed 400mm/sPositioning precision 0.01mm35w Laser tube power (For upgrade to 60w ask for quotation)Lifetime of laser tube 35w 1000-1500 hoursMinimum character size 1.5mm by 1.5mmSoftware supported: CorelDraw, 2D Design, Art cut, Auto CadGraphics supported: DXF, PLT, JPEG BMPDriving method by stepper motor70mm adjustable Z-depth tableRed dot pointer system for easily and quickly lining up your workHoneycomb worktableFlow sensor to protect your laser tube12 month warranty excluding consumablesAir assist to direct a constant stream of air and control heatUnlimited UK technical supportFully trained specialist laser engineersPower supply 220v (or 110v) +/- 10% 50Hz (or 60Hz)Net weight 60kgGross Weight 100kg

Adam, who owns this, thinks it might be the 60w upgrade version! EDIT: also ‘air assist’ as mentioned in those specs.

The webpage gives slight different external dimensions, but I imagine it’s been through some iterations over the years.

So do we have a decision?

Well it depends on the @directors because they need to decide if the vote stands or we are going to redo the vote with the third option and clarifying that this means smaller or no CNC.

Or we could have another referendum on brexit"…

Would this be to assuage your guilt?

Too Late.

Sorry couldn’t resist

Haha yes well i did ask them to make a call during the vote but no one did.

The result of the vote is fairly clear, but we have to be careful about how to manage this. This is what we’ll do:

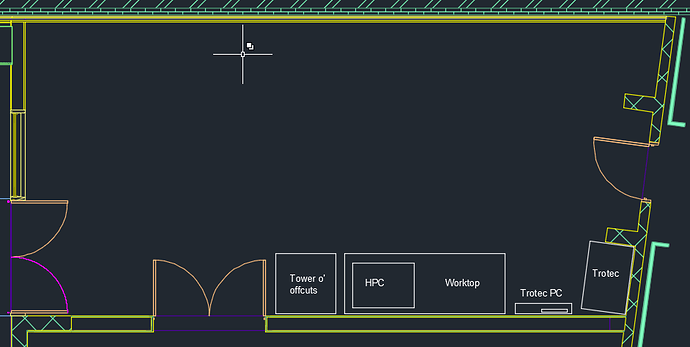

- Prepare the messy room. The broken sander and big steel “windchimes” need to leave the space. The drawing board needs putting away or getting rid of. The Tower-o-offcuts needs to move towards the Dusty doors (this will eventually become the enclosure for the CNC machine).

- Provide worktop for the HPC and general assembly use. This needs doing anyway. 2.4m long, 900mm deep, 860mm high.

- Adapt extract system to accept output from the HPC. It has its own fan and hose (diameter unknown but looks like 100mm).

Only then can we bring it into the space. From that date, there will be a 6 week testing period, after which we will will review and decide whether we keep it long-term or pass it on to another space.