I thought I would follow up my recent post where I mentioned a new white aluminium oxide wheel I was given. The grey wheel needs dressing as it’s shiny, and it’s loading; just noticed that. Coarse is the hardest working wheel so, I dress often.

I was awaiting bushes to reduce the hole in the white wheel to 1/2 inch. The bushes I received from Axminster are the better kind. A pair of nylon bushes which reduce from 32 to 12 mm in one step; they push fit either side of the wheel. Generally wheels like the draper wheel are supplied with the not so good option; five reducing bushes sitting inside one another, all of which are needed to reduce to half inch.

I had to use a file to finesse the fit of the nylon bushes, they were much too tight and could easily split the stone; that would be a disaster. I spent 15 minutes, with a couple of files, adjusting the fit.

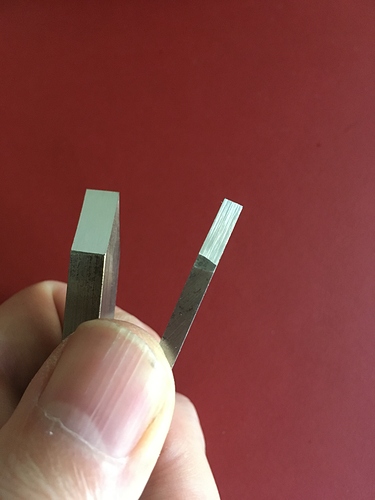

The white wheel is specified as 100 grit and this seems accurate when compared to my existing 80 grit wheel; the white wheel produced a visibly finer grind. As to the heat produced, I would say the white wheel is not grinding cooler in a way which significantly impacts the function. Any reduction in heat using the white wheel is very small.

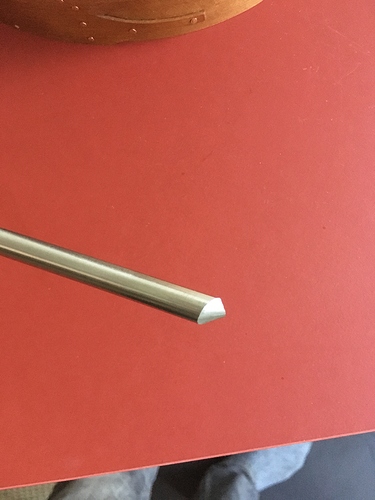

I found that grading the stone produced a finer more even finish. I noticed the stone seemed to grab and the quality of finish deteriorated after a couple of minutes use; just a couple of seconds with the diamond dressing tool produced a noticeable improvement in finish. For the purpose of honing I will always dress the stone now I know how effective this is. The white stone ( rated f or soft) is softer than my grey stones ( rated m, hard ) but it has a density rating of 5 ( dense). So, the density and softness balance; the stone should last. Overall I am very happy and it’s a step forward for sharpening wood turning tools.

4 Likes