I got a couple of nice saws, I was assured I was getting a crosscut, I got a rip. The advert then stipulated crosscut, I got in touch and checked it was definitely crosscut, it is a rip. 120 of these saws have been sold, I am the only person to notice they are rip saws not crosscut. They walk among us.

The most recent saw to arrive was as blunt as a Bernard Manning put down. So I set about turning it into a crosscut. I phoned garlic and son to find out the rake angle, and the person I spoke to told me that they are hand sharpened?She also told me that she is fond of fried food and once had a crush on Jamie Theakstone. However, no tooth geometry was forthcoming. I think this proves that garlic and son are a top notch outfit and destined to grind the likes of lie Nielsen and Veritas into dust.

Anyway the rake is about 12 degrees as far as I can make out. High for a rip tooth but perfect for a crosscut. I decided to put 15 degrees of fleam which is a jack of all trades. I jointed the first saw, raced ahead and wasn’t happy with what I got. I then reshaped the teeth back to rip. It turned out really well despite the circuitous route. I decided I would concentrate hard on the other saw. I coloured the teeth with Sharpie and then lightly jointed the saw. I realised I was getting a bias on one side of the file which had cut some of the teeth small ( I realise that crosscut teeth appear one small one big, this is an illusion, what I had got first time round was teeth literally smaller than their neighbours, visible by holding the saw up to a bright light with a straight edge touching the teeth, showing some teeth not touching the straight edge) I concentrated on removing an equal amount of metal from both teeth and I did much better. I screwed up the first six teeth below the handle, it is not a big deal as I know why and they don’t get used. I forgot to flip the rake guide around when I turned the saw around. I had always wondered why people write on their rake guides. I never used a rake guide or put a handle on my file before. I thought about the rake. If you don’t use a rake guide, you are trying to align the top of the file. It’s 9/32 wide and it’s not horizontal, you can’t see either of the file edges cutting the teeth. It would be easy to align the file wrong I think plus or minus five degrees would be good going. That’s a rake which may vary from 8 to 17 degrees. That’s a big discrepancy. With a rake guide you just align a two inch long piece of wood with the top of the plate. I think it would be realistic to expect a variance of less than 4 degrees. I actually think it’s more like one or two degrees. You can see the rip saw teeth confirm this. They are in the bottom saw. I found using a handle gave me much more control, definitely something I will continue when sharpening high tpi.

The next two or three sharpenings I will sharpen those six messed up teeth in a rip configuration, until they are the correct size and shape. Then I will sharpen them in line with the rest of the crosscut teeth. I learned a lot from doing this, both the saws cut beautifully now, I just thought cutting crosscut teeth would be the same as sharpening a crosscut. It’s harder than sharpening a crosscut.

Whilst I’m on the waitlist I’m thinking of making a mini workbench and doing some hand tool woodworking in my flat. Saws are high up on the list of handtools I don’t really have (super crappy ones!). The thought of having to sharpen western saws for them to work well, plus the cost, was a bit intimidating and was making me think I might try out Japanese saws. Do you think this is a fair worry or have you found sharpening not too difficult? Is the kit expensive to do it?

Thanks for the super detailed answer. You make a really good case for the western saws and learning to sharpen them would be a great skill to have! I also like your approach of whittling it down to the couple you need, so many sites will tell you that you need 10 options! It very much aligns to my principles so far of limiting the total set of tools but buying good ones.

I’ll get on the research of options, do some reading about sharpening and put something on the xmas list (although it might be a gift for myself!). In the meantime, I’d be very tempted to take you up on your offer re the Japanese saw you have, let me know how much you’d like for it

You can have the saw with the extra blade for ten quid. The crosscut blade is the one I use most often and is most suited to softwood and things like Cherry or Sapele or anything not super hard. It’s also very good for mdf. The rip blade has had a few microns of the set removed by me. Both the blades have plenty of life left in them. A bit of wax on the blades helps. I am in Greenwich, If you want it let me know.

Sent a separate message re the Japanese saw (am keen).

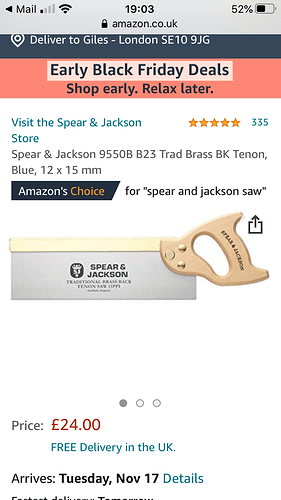

Have also done some major procrastination and got very into the idea of getting the Spear and Jackson you suggested and then following the suggestions of this video to:

- Convert to rip

- Reshape the handle

- Upgrade the fixings

Seems like a nice mini project and good induction to all things saws.

@Giles, it’s taken a while but saw files arrived and I now have a rip cut!

I now have two identical panel saws, 1 rip, 1 crosscut. Results are very noticeable… On the left is 20 strokes with the rip cut and the right is 20 with the crosscut (44mm beech)

My only slight worry is that it appears to have reduced the set quite a bit, hopefully there is still enough!

Crosscut both saws got much further in 20 strokes and the crosscut saw did indeed go the further of the two so glad to have both

Will sort out the tenon saw at some point soon hopefully with a slightly more practiced hand

I am happy to hear from you. Having a community of woodworkers and the space makes sense. I really do hope you are able to join. until then at least this forum can be of help. I see the reduction in kerf, if it does become an issue, you can meet me one time when i amover at the space. I will bring my saw set over. it is not in the least bit complicated. I imagine as this was your first exploration into sharpening your saws, the learning curve is extremely steep for the time being. i hadnt given it much thought until right now. because the fleam on the spear and jackson is considerable you remove a big piece of metal. what is the fleam on the spear and jackson. twenty five degrees, thirty, it is very pronounced?

Are you using a guide in order to keep the rake consistent?

yes looking good.

No idea on the angle but as you say its fairly pronounced and I had to take out more than I was expecting to. I didn’t use a guide but felt reasonably good (perhaps naively) about my angle. I found an older rougher spear and jackson at my parents that is already configured for rip but is super dull… when I do that maybe I’ll try a guide.

There were two saw sets in the space(in a large white plastic container wit other sharpening bits)

Yeah, thanks. Are you making anything at the moment?

Tagging onto the end of this and that Rex Krueger vid: personally I think those modern handles are waaaay too large. I have a vintage handle which is much snugger to the hand, and gives you much better control. If you can find a nice lump of wood then making your own handle to an old template is super rewarding.

I was thinking about one of the replies I got referring to the set on saws. The point I was making was completely missed. Cutting a dovetail doesn’t require a great depth of cut and the saw plate is free of the kerf for the most part. Therefore adjustment can be made if the cut were to drift. Now imagine making a dimensional rip cut, where the blade is completely inside the kerf. A Japanese saw with microns of set or, a European saw with microns of set. They will both cut accurately in friendly timber. However, try to saw accurately in wood which causes severe drift and you will be nothing but a spectator as the cut wanders. What do we do when we encounter severe drift? We angle the saw plate away from the drift. It’s impossible to counter severe drift if the saw plate is travelling within a tight kerf. This is not an opinion it is a statement of fact. Saws with a gnats knee cap of set only function in friendly timber. I don’t want tools with reduced function. I want my saws to cut accurately regardless of the timber. So, the modern obsession with thin plates and microscopic set is daft. It renders a saw with less function, it adds nothing. You may think this incorrect, wait until the day you encounter severe drift in a piece of wood. Think of a swimmer with a top speed of five miles an hour in a fifteen mile an hour rip current. They’re going backwards at ten miles an hour. It’s similar to what happens with a saw plate in a tight kerf, in unfriendly wood. The angle of drift can easily exceed the amount of correction possible. I still use my Japanese saws, but let’s not pretend they are great in all areas. My Disston D8 will outperform my Japanese saws in any drift situation. It works so well in ANY timber, severe drift is a non event. Something I can’t say about my Japanese saws.

Finally caved and bought an old panel saw to trim up, and wanted to echo what’s been said about set and kerf. When I received it is had precisely zero set to the teeth - nothing at all. First short cuts are from this - the blade jams almost immediately in pine.

After sharpening and setting (at what my set thought was right for 10tpi) I found it still wasn’t clearing the cut well. Some of this is from a less-than spotless plate, so I have more work to do there, but adjusting the set to something supposedly more appropriate for 8tpi was a big improvement. You can see how the cut gets cleaner with less rubbing on the plate.

Annoyingly, my sawhorses are currently acting as a stand for my toolchest, so I can’t really get to grips with it yet.

Oh, and a pic of the saw: