An idea was to put a switch on the shutoff valve so that also turns on and off the fan and extraction… so which one would make that easier?

Resin printer extraction

Hmm, I’ll see how it fits.

There is a 45 degree joint for going into the hood which was the perfect length and angle. Should be with the other parts around the printers. Couldn’t make it tonight but can come down tomorrow. We can splice the valve in somewhere.

There was a longer piece that goes straight from the right angle up the to to right over the hood. We just need to trim the pipe comming out the wall a touch.

Tube of sealent is by the resin printers still. I will book out the laser cutter for tomorrow so we can connect it up

There are some old limit switches in one of the boxes above the ultimaker we could use possibly.

O lord that was a lot harder than I thought initially, but it’s done. Pipe work is sealed nicely up to the shutoff valve, and then it’s just good enough to work. I used the old shutoff valve just cause it fit as it was without extra cutting (but switching it out is easy on this side, it’s just taped together).

Thanks everyone who helped!!!

Anyways, I declare the resin printer commissioned! Hoozah!

I’ll come in tomorrow evening to do some printing.

^ I put a big glob of sealant around the inside perimeter, then clamped and rivetted the 4 corners, then taped around it. Seems to be sealed good.

Cool nice work. we do need the main extraction unit to be wired in so we are not 100% there. If it’s not connected, the main vent at the front of the building doesn’t open and the main fan doesn’t turn on so we are just blowing the fumes into the ducting. And potentially around the rest of the whole of the arch.

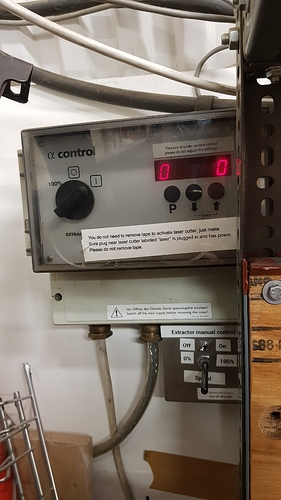

Great work! Same with welding, you need to manually turn on the extraction… so make that part of any inductions until it is automatic.

If you’re not familiar with the manual extraction control, use the toggle switch in the corner between MIG and lathe and adjust the pot to “F” for full power.

Let’s get that risk assessment signed off!

Good point!

@scday94 can you review it?

https://discourse.southlondonmakerspace.org/t/sla-resin-3d-printer-risk-assessment/25419

Thanks!

Andy

Can you make it editable by me or should i copy and paste additions below? or i can quote ammendments below.

@Calin, Has a tool page been made for the printer already? We will need the COSHH data sheets for each of the different resins for the printer. Might also need to make a second one for the wash and cure station.

Started one will need another for the wash and cure station.

Eh put them both on the same page. I only made the risk assessment page, yea, i postponed the tool page. I’ll write down induction steps while I’m doing a print, I’m just heading to the space now in case you’re also there

…

Don’t know how to make the risk assessment editable

Hey @asander1, Sam has had a look over the risk assessment. He pointed out we’ll need the material safety datasheets on hand for the resins that we use, so we’ll link to them on the tool page and have some print outs by the printer. Should be good to go now.

Cool I will take a look!

yes they have been put in the 3d printing group page including any handling guides. Will print outt he data sheets now if the printer is running at the space. We have also runs some tests and the extraction seems to be sufficient when printing. I dont know if we have any airborne pollutant detectors that can verify the effectiveness or is that over kill? if anyone want to have additional ventilation, the chemical data sheets provide details of the type and grade of respirators needed.