Anyone have any experience with polyurethane Liquid rubber Casting. It’s more the mold making I am requiring assistance with… can a mold be made of acrylic/ 3D printed from PLA?

I tried a couple of times… any mould is fine , only thing if is a weird material try with a scrap piece and few drops of resin if resist the solvent…

As a non sticky coat I always used wd40

I am about to make a mold , how much does its stuff cost ?

Sorry are you making the mould from the polyurethane rubber? What are you making a mould of? Do you want to know what is good to use as a container for the mould? Acrylic will work.

Hi Beth, I am trying to cast polyurethane rubber in a mold I need to make. I was going to laser cut some acrylic to make a mold. Do you think is possible to cast the polyurethane rubber in such a mold?

Here is the polyurethane I am going to use…

http://www.mbfg.co.uk/polyurethane-rubbers/duroflex-85.html

Yes I think so if you use a release agent. Always best to do a small test first though.

Hpw did you get on with this?

Awaiting delivery of my chemicals etc will commence testing on Thursday…

So did u need to use a release agent? Is your mould made of 2 layers of acrylic?

My first mold was a base layer of acrylic and an additional layer of 5mm acryic. I used a releasing agent and the 50’ that I used came away easy. The base where the releasing agent was used doesn’t look as good as the exxposed side as in the images above.

My next cast is 80’ and has a base and two layers of Acrylic… will post images when it’s done…

Great! Look forward to see more!

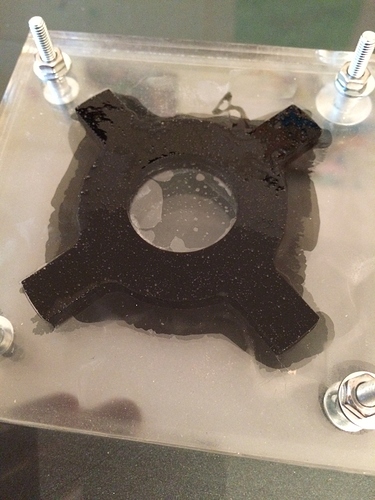

Update on the casting…

Using acrylic moods work well, if using a polyurethane rubber of low shore value, the piece comes out the mold easily and you don’t have to use a releasing agent if the mold is simple. If using multiple layers of acrylic to build the height of the mold, it’s difficult to stop the polyurethane from leeching between the layers. I bolted the layers together and still get a little leeching…

The latest cast I have just done is with a polyurethane mix which has a 85" so it’s really tough. The cure time is 4-6 hours with full cure after 24hrs so will keep you posted… mold this time include a plywood base treated with a wax release agent to seal the wood. Pics below, will post the results tonight. I have a load of polyurethane left, does anyone have an idea of something they may want castes in around a 50’(so quite flexible)?

Might be worth “painting” the interior of the multi-layered mold with plastic welding solvent to seal up the gaps.

Very nice…and what are they?

I think they are Wallace and Gromit style sucker-feet. So you can walk on the ceiling.