Notice

- This machine should not be operated without induction.

- This tool should not be used while alone in the space - lone working rule.

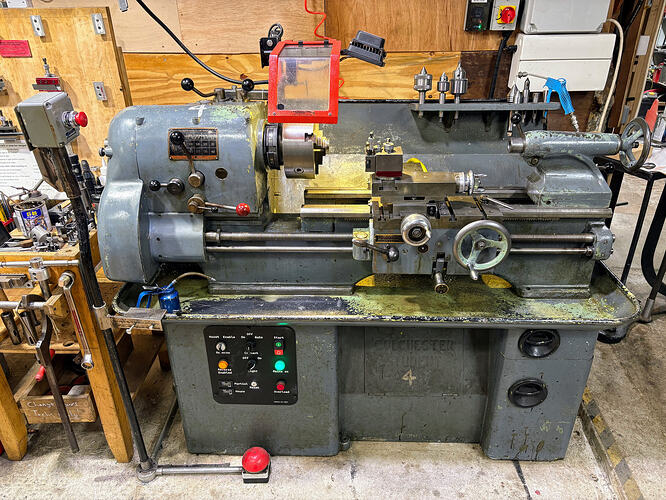

Colchester Student Cub Lathe

Details

The Colchester Student Cub is a gap bed metal cutting lathe without a quick change gearbox. It has power feed and can be used for turning, facing, boring, die cutting as well as tapping of both metal and plastic sections.

The three jaw self centering chuck is installed as standard and is used for circular and hexagonal cross-sectional material.

The four jaw independent chuck is for square and irregular cross-sections. The installation of the four jaw is a tech only operation and needs to be booked in advance.

A range of carbide insert and high speed steel tooling is available for facing, turning and boring.

Thread cutting is possible but is only available as a tech assisted operation using manually configured change gears. This process must be booked in advance.

It also has a suds pump for workpiece cooling.

Specifications

- 152mm (6") centre height with turning diameter 305mm (12") over bed, 229mm (9")over carriage and 203mm (8")over cross slide.

- Distance between centres 610mm.

- Diameter of faceplate 305mm (12").

- Diameter of 3 jaw chuck 190mm (7 1/2").

- Diameter of 4 jaw chuck 254mm (10").

- Head stock bore 35mm with a No. 4MT taper in spindle nose bush.

- Tail stock fitted with a No. 3 MT taper.

- 8 speeds between 54 and 1200 rpm.

- Fitted with an 3HP 3 phase motor.

Additional tools:

- Quickchange toolpost with multiple tool holders.

- Tailstock 3MT 5-20mm drill chuck.

PPE

- Safety glasses are mandatory

Safety Checklist

- Do not wear loose clothing.

- Ensure long hair, jewellery, and any clothing drawstrings are securely tied back

- Sensible footwear with sturdy toes should be worn at all times in the workshop. Steel toe-caps are a bonus.

- Do not wear gloves - they are an entanglement risk with metalworking machine tools - if you are concerned about grease and oil use barrier cream

- As with any power tool - be alert. Do not use the lathe when tired.

Condition Notes

Given to the SLMS by the Society Of Model and Experimental Engineers, SLMS paid to transport it. From the 1960’s in very good condition. Has been extensively overhauled and reconditioned by SLMS members.

Maintainers

Risk Assessment

Induction and Training

(Note: The following is effectively the contents of the induction process)

Induction is mandatory. The induction covers safe use of the metal lathe as well as some basic processes. A metal lathe is extremely dangerous if not used properly. Statistically, it is responsible for the most life changing injuries and deaths.

Safety:

- Risks: Entaglement, flying debris, heat fire and sparks, trips, sharps.

- Mitigating Risks: Eye protection. No loose clothing, cuffs, jewelry, long hair or drawstrings. No gloves. Sturdy shoes.

Before Use

- Clear the work area of anything that may be in the way.

- Don’t ever place things on the machine.

- Make sure the machine is clean and free from metal chips, dirt and particles.

- Check the tools you intend to use are in good working order.

- Have your work area set up with the things you need i.e.cutting paste, brush, tools, blue paper roll.

During Use

Controls And Switches:

- The tool control where you tap in is on the wall behind the machine alongside the main red power switch.

- The control panel with the start stop buttons, status lights, coolant

Textand light switch.

Parts Of The Lathe:

headstock, chuck, saddle, cross slide, compound, toolpost, (slide)ways, tailstock

After Use

Maintenance

References

manual

9485.pdf (4.0 MB)

eg. instruction manuals, tutorial videos etc.