hi guys,

going to make a completely metal lamp from scratch as my first project of freshmen year in enginnering. however, im wondering how to approach the detachable base problem and the lampshade. Should i mould out the lampshade? what other method can you suggest? has to be metal though.

Thanks guys

Well… maybe if you share some pictures, sketches or even an idea of what you want to achieve, someone can try to advise you.

Do you want the power to go through the detachable connection?

What shape of lamp are you looking for?

im wanting to make sure the wiring is 100% internal and gets detached from the base as well leaving no tangling of wires.

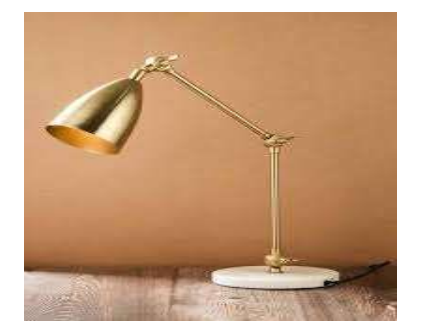

for the lamp shape, im wondering which shape i should use since the lampshade would be metal and making it cylinderical would reduce the field of light from the bulb, rest i could do something like a bowl shape but thats where im wondering how i will produce that. attaching image for context of the shape of lampshade im looking for

I’ve no idea how to do the bowl or cylinder. In theory could be done on the large but would involve techniques beyond my ken.

But for the base the usual approach is to use tube with enough of a wall thickness that you can make narrower section with an external thread on the part that goes into the base and screw a nut on it the other side with a recess in the base for the nut.

What’s the material?

not easy to make the base detachable with connectors for the wiring too.

Mainly because mains wiring is dangerous and needs to follow specific rules!

can the lamp be low voltage? 12v or 24v would be a lot easier

sheet metal mostly, i can request for some other materials as well if you can reccomend

no… has to be powered by mains not battey… will need to figure out the base issue

thanks

thank you james!!!

you could always step down the voltage with a power supply

hmmm i cant mess with the power supply, everything of the project needs to be in the lamp only, i dont know if i can fit that system in

Cylinders are a lot easier to make, I’d definitely recommend it. Larger features would historically been made on an English wheel but aluminum reflectors are made much quicker metal spinning. We don’t have the equipment for either unfortunately. Cones can be made on on a bending brake. Improvising that would still be a significant challenge but a better middle option. What about approximating a cone with increasing radius circles? This kind of esthetic: