Hello.

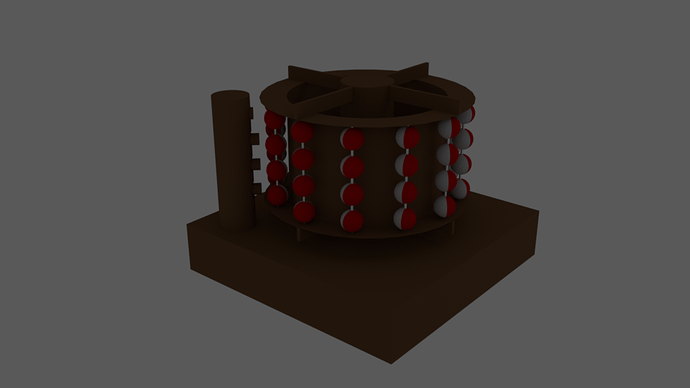

I’m trying to build a mechanical dot-matrix display of 32x8 pixels. Each “pixel” is a spherical wooden bead with a hole through, painted on one side. Rows of eight beads are mounted on vertical metal rods, and 32 rods are arranged on a rotating cylinder. The beads are fixed vertically but free to rotate around the rods, so that they can either appear painted-side in or out. (*1)

The cylinder sits on a rectangular base and is turned by a motor; it constantly rotates clockwise so that the message appears to scroll from right to left. It can be slowly updated by a tower, also protruding from the base, containing eight photosensors and solenoids, which detect the current state of each bead as it goes past, and gives it a push if it’s in the wrong position. (*2)

*1 I’m not sure how to do this but I maybe I can glue smaller plastic beads to the rods to act as spacers, and the beads can balance on them.

*2 As the display is rotating, I just need to gently push against each bead to force it to turn in the opposite direction. This might not be enough to turn a full 180 degrees but as long as it eventually gets there, that’s fine. The photosensor detects what fraction of coloured/uncoloured bead it sees go past, to tell what angle it’s at. I can hopefully use an LED blinking at a given high frequency to cancel out the effects of ambient light.

Does this sound completely crazy?

But in a good way.

But in a good way.