Is there anyone going to be around on Sunday, a couple of pieces I cut the other day were wrong and need to re cut them again.

Sunday.

Tomorrow would be better actually if it is possible.

No one is planning tone there

Yay induction processes! The perils of growing membership.

I’m assuming my official membership is still a few days away from filtering through the system. Would I still be able to come along for an induction? And I take it announcements like these fall under general discourse?

What’s your real name?

(If you want, you can add it to your profile here btw)

I can find out when your payment goes through.

What about Monday, or is Wednesday’s open evening the next best time to come.

Goldie Chaudhuri in the profile.

Aargh it’s that annoying auto-hiding of real names that are similar to usernames thing again.

Nah… Doesn’t show my name and I am not similar…

OH yeah, we turned real names off didn’t we. (cos of this issue)

Sorry, as you were!

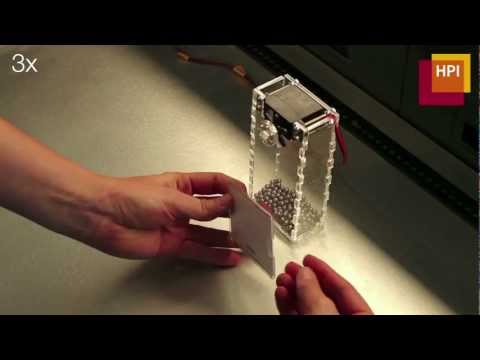

I spotted that video over the weekend will doing some looking around for laser cutting project. Maybe a source of idea for other

That’s really cool, although I don’t think we have enough direct control over the machine to be able to do this.

Actually that machine is a Universal Laser Systems machine, it’s not more or less able than a Trotec, it has very similar software, it’s just that this was research done in the US and happened to be on a ULS machine so it probably doesn’t have a Trotec equivilent. Also the Trotec has a darkened top window, where as the ULS has a plain glass window.

From the video it look like the sheet is just resting on raised pin. Based on the instruction manual of the laser cutter we could just move the working table down to compensate for the offset ( only speculating )

http://www.troteclaser.com/en-US-GB/Laser-Samples/Acrylic-Plexiglass/Pages/napkin-holder.aspx

This might be of interest. Seems the bending is done by defocussing the laser along the bend line, and then allowing gravity to take it’s course.

Looks we do have sufficient control over the machine to be able to do this

This makes me want to do a really complex multiple stage folding operation…

Like, you could achieve bends other than 90° by first dropping “guide” pieces either side. Lots of cool possibilities.

Or you could make a “bowl” shape by cutting out a flower or star then progressively bending the petals down. @Matthew_Stannard could find some interesting lamp shades in that design space

Looks interesting. I have got a shop in Godalming interested in selling my lamps, so I’ll have to keep innovating.

There is a difference between the defocussed laser bending which it can do, and the special software that is doing this with computer vision and also the other aspect of this project where you can draw with a special pen what you want and it cuts it.