This tool is out of service until its risk assessment is accepted

Details

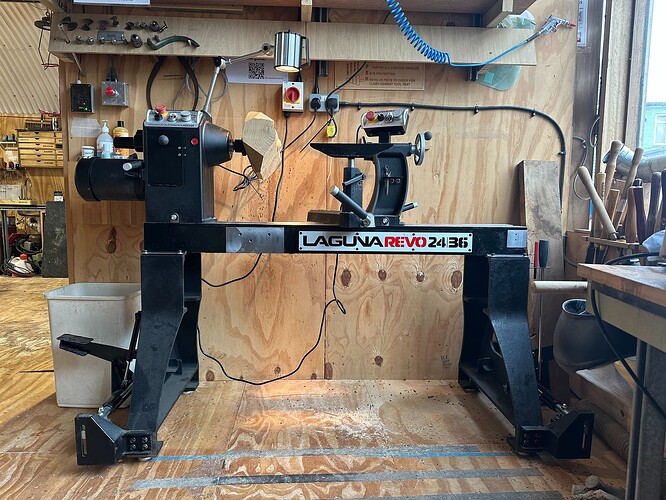

Laguna Revo 24|36 wood lathe.

Purchased new in 2025 following a successful pledge drive.

Induction and Training

Induction is required before using the wood lathe. Use of either lathe requires signing into tool control.

There are two levels of induction, which must be performed sequentially.

- L1: Turning between centres - Covers tool sharpening, lathe safety, side-grain spindle turning.

- L2: Faceplate & chuck turning - Covers advanced gouge sharpening, chuck use, face grain turning including bowl making.

The inductions are described in detail in the Woodturning Study Guide.

Inductions from the the old wood lathe carry over to the new lathe. Please read the documentation below.

Maintainers

Safely using the wood lathe

This tool requires suitable PPE:

- Eye protection is compulsory, face shield is preferable. Multiple face shields are provided.

- Dust masks are recommended, and compulsory during sanding.

- Suitable footwear (workshop appropriate with must have strong heel) must be worn.

Before use

Attach your workpiece, and make sure it will safely resolve following the guidelines below.

- Personal safety

- No loose clothing, jewellery, gloves, or neckties.

- Long hair and beards tied back.

- Machine safety

- Clear machine bench of any loose items.

- Ensure the spindle index is not engaged.

- Check lathe and tools for damage. Be safe, do not use any tools that appear to have damaged components.

- Select the correct drive, chuck, or faceplate for the task; and ensure it is tightly attached.

- Where possible, select and engage the appropriate tailstock.

- If the tailstock is not in use, ensure it is locked in place at the far end of the lathe bed.

- Ensure the speed is correctly set (see Setting the speed).

- Ensure the tool rest is set to the correct position (height and distance) from the work. Rotate the workpiece manually.

- Ensure you have adequate space for the cuts you intend to make.

- If you are sanding or finishing, remove the toolrest.

- Material safety

- Check your stock fits within the safe working dimensions for the lathe, according to the task you are performing.

- Ensure your stock is not cracked.

- Ensure your stock does not contain metal.

- Remove any loose bark or knots.

Before use: Troubleshooting

- The wood lathe will not revolve manually - check the spindle index is not engaged.

During use

- Stand aside while first turning

- Keep firm hold and control of the turning tool at all times. This is especially important while turning with knots and voids.

- Always keep tool in full contact with the toolrest when applying to the workpiece.

- Do not touch moving parts with hands and fingers.

- Do not leave machine running unattended.

- Use the correct tools for the task.

- Do not stretch over the rotating workpiece.

- Do not adjust the toolrest while the machine is running.

- When using calipers, turn the machine off.

- When sanding:

- Enable dust extraction and wear appropriate PPE

- Ensure your hands are positioned so as not to be pulled into the direction of rotation (usually underneath the workpiece).

After use

- Turn off lathe

- Clean lathe, tools, and areas

- Brush down bed

- Return all tools to storage

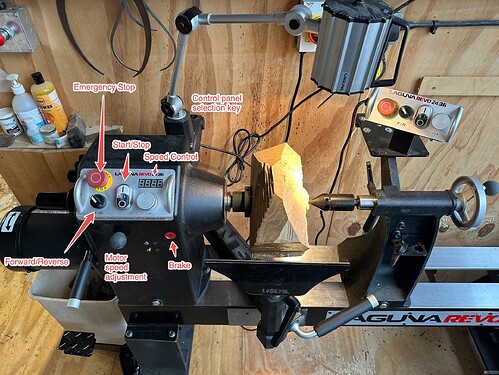

Controls

The lathe has two control panels, one on the main control stack and one beside the tailstock. Only one of these control panels is operational at once. While the lathe is idle, switch control panels using the key located behind the headstock.

Both emergency stop buttons, on the headstock and tailstock, are operational at all times. (Someone verify this?)

The control panel contains the following features:

- Start/Stop

- Speed control

- Emergency Stop

- Forward/Reverse

Selecting lathe speed

On this lathe, adjust the speed using the speed control dial. It is exceedingly rare that you will need to swap pulleys.

The speed range supported by the default pulley is 350-3000 rpm.

Use your judgement to select lathe speed. In general, the narrower the stock you are turning, the faster you should run the lathe. Over the course of several cuts, you will likely need to adjust the lathe speed.

Setting the tool rest, tailstock

Use the levers on the front of the tool rest and back of the tailstock to set their positions. Make sure not to overtighten these components, as this can lead to mechanical wear.

Use the black handle underneath the tool rest to reposition the rest itself, including height adjustments.

Changing drive, chuck, faceplate

Ensure you intend to switch to a tool that is correct for this lathe. With few exceptions, tools for the Tyme Avon lathe are not usable on the new lathe.

To remove a drive, use the long knockout bar stored on the end of the lathe, while holding the drive (to catch it). Please ensure the drive is not allowed to fall to the floor, as it may damage itself, the lathe, or a body part.

To remove a chuck or faceplate, while holding the ‘Brake’ button (see control image), pull the top of the workpiece towards you.

Risk Assessment

TBC - new risks (from old lathe) discussed today:

- headstock has increased risk of trapping a hand

- larger blank diameter increase risk ( sign to reduce speed)

Identify risks

State control measures

Maintenance

- Keep the lathe bed clean by protecting it when using painting or finishing oil

- Wipe the lathe bed with a clean cloth lightly moistened with mineral spirits / white spirit to remove oil residue and dust.

- Spry WD 40 and eventually dry PTFE on the lathe bed

- Clean the tool rest top edge with fine steel wool (0000)

References

Revo 24 36 Instruction Manual (5.3 MB)