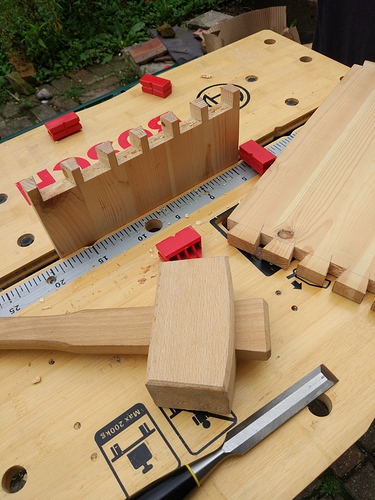

I made a box for storing some tools in and was pleased with how it turned out as it is my first attempt at cutting dovetails. It is a bit rough and ready here and there but I learned a lot from doing it. It is a functional box not a decorative one, so I got very close to what I was aiming for.

One set of joins is a little bit more gappy than the others but I think that is mainly down to me not squaring off the wood 100% - one of the pieces still had a bit of a bow in it. I did the best I could with my hand tools.

As it is in pine, it was quite easy to chip little bits out if not careful.

I would design the handle part differently next time, but there you go. I 3D printed a jig to help shape the handle hole with the router.

I used the Paul Sellers method, and it worked well as long as I made good saw cuts. The only thing was the chiselling out took a looong time.

I’ve since seen this Rob Cosman video and it looks like a good method. Using a coping saw to cut out the waste could speed things up a lot.

I wondered if there was a way to use his method on the cheap without buying his custom saws. He uses a knife with the same blade as the dovetail saw to mark the cutting lines for the pins, before cutting out the waste from his tails. See this bit of the video.

I got one of these saws for my birthday recently so I used that to cut the dovetails. I wondered about using one of these flush cutting saws for the marking knife. It’s the same thickness as the saw but the teeth don’t have the 0.1mm set on either side so it would be 0.2mm out. Probably not accurate enough?

(he does the same thing with a hacksaw and a screwdriver filed to a chisel shape)

(he does the same thing with a hacksaw and a screwdriver filed to a chisel shape)