Hey all and hi @CNCtechs,

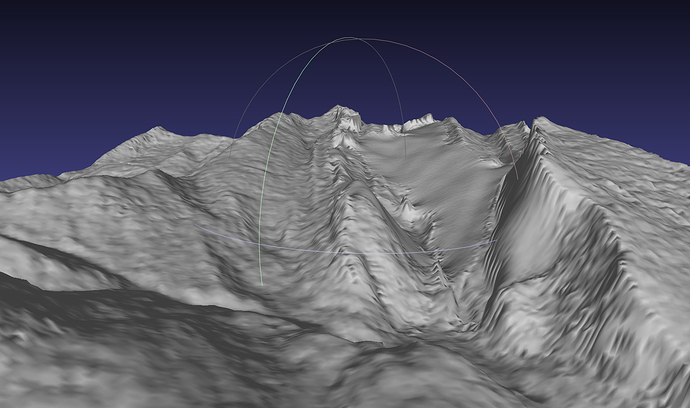

I am working with a topography map in .stl format. It is possible to import it in Vcarve but I wonder if it is the best way forward. My other option would be to work with fusion360 and then import the toolpaths in Vcarve.

Does anyone have experience with this and can suggest a workflow?