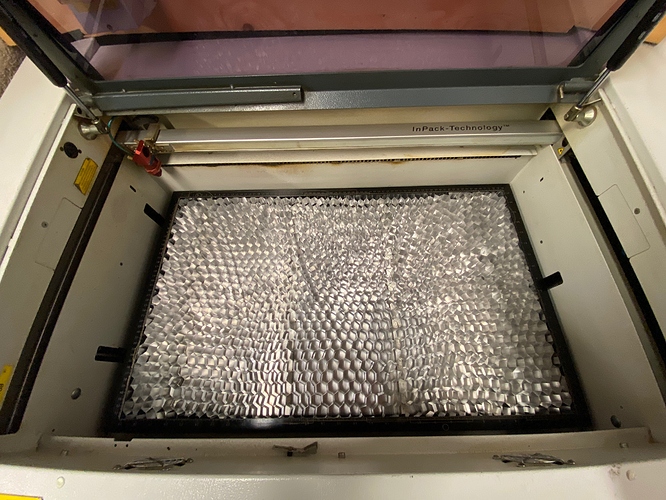

Does anyone (perhaps the gracious @lasertechs) know when the honeycomb in the laser cutter was last replaced? The last time I was in, it looked extremely grotty and uneven with several large holes. A quick search here on discourse indicates that people have been muttering about replacing it for a year or more.

A brief and cursory google search leads me to believe they may not be very expensive, but I have no expertise on the matter. Either way, is there somewhere I can pledge some cash if it means getting a new one sooner rather than later? I’m only in the space once a month or so, but it’d still be worth it: I feel like my laser jobs have been getting progressively more scorched on the underside as time goes on, and I suspect the venerable honeycomb has at least something to do with it.