I’m tinkering with project that would need a couple of small lightweight aluminium brackets made. I have close to zero experience at this. Can the tools we have cope with drilling/tapping this material or cutting it to size ? I know its quite a soft material, is there anyway to harden it after the part is machined ?

Machining aluminium?

yes, we have a nice mill in the space now, and several tap sets. hardening is another story though. heat and quench in oil?

No, you can’t really harden aluminium.

Does tapping holes in it usually hold up ok ? seems like a misthread could easily wear it out but maybe i’m just being over cautious

Depends how thick it is. Also ‘aluminium’ is rarely pure aluminium and often has other things mixed in with it to improve it’s properties.

What are you planning to do?

I need to attach some small brushless motors to a frame for a camera stabilisation system. The parts I have don’t match the pre drilled holes on the motors so I need to make my own.

I probably don’t need to tap anything but I’d like to have it as an option if I need it

Sounds like aluminium might be your best bet. Nice and easy to work with hand tools. You might get away with drilling and tapping but if you can include nuts in your design it will probably be a bit more robust.

Happy to take a look at a drawing before you commit to metal if you like.

Aluminium sounds like the like it will be fine for that sort of thing, I will be happy to help you with cutting drilling tapping ect

Taps work fine in aluminium and it can be anodised to for a durable finish

working on a similar project here.

Great, thanks joe & rich, I’ll work on the plans.

@Marco_Pagliari it’s a brushless gimbal system a bit like a cheapo version of the dji ronin

it sort of works ok but i’d like to make it more easily ajustable

I’ve been looking into building a gimbal for past few weeks. been working on some placebo code to try get a minimalist version working I use to have a dual servo setup on mu Quad but want to setup a brushless design

I’m using the basecam electronics Alexmos system. You can buy the board or I think you can make it yourself and just pay for a licence to activate it via the software

https://www.basecamelectronics.com/

Its pretty straightforward to set up. On the otehr hand finding proper hardware for the frame is a nightmare. Which is why I need to build parts. I can’t even find the right hex head screws for my motors online…

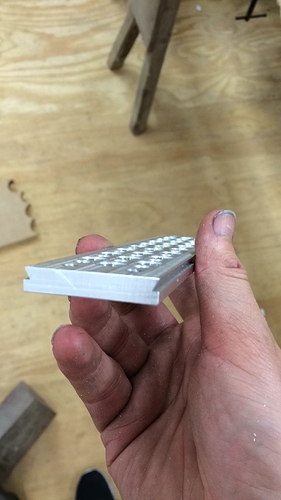

Thought i’d post an update to this. I’ve been learning quite a lot these past two weeks and I’m starting to get comfortable using the milling machine with aluminium. Tapping it also works great, but the surface finish is very prone to dents and scratches and needs a treatment to make the parts usable. Here’s the latest bit I made which is a sliding dovetail plate for the camera tilt tray. Its supposed to be as light as possible (hence the holes).

Nice work!