I don’t have experience per says with those kits in particular but I can comment on the type of printer and the hardware they are coming with. So I will try to give you quick break down below as concise as I can, if you feel reading until the end I’ve put a few alternative options otherwise take into consideration the following.

Buying a cheap printer don’t always end up being the cheapest options because we omit too often the cost of our time and this will be potentially reflected exponentially when buying a printer if things do not work as expected. The first question you need to ask yourself is do you want to print stuff or possibly having to learn how to build a 3d printer to build stuff. Second are those things you want to print are for your own prototyping/creation or to produce for a client this will define the amount of reliability and reproducibility you’ll need to have. Finally don’t think because someone as positive experience with a specific clone cheap printer that it will apply to you. Buying a kit from the same aliexpress, baba , bangood etc … is an absolutely unreliable experience. The only one I can put my name next to it is TriangleLab

-

First link is a Prusa I3 architecture style and this one in particular make me think of a cheap CR10s

- The biggest draw back of that architecture is the wobble of the z axis (in short when you bed move forward and back the extruder carriage and the top part of the frame follow the movement of the bed creating some banding on your print) this defect increase the faster you print and consequently the higher your carriage will be

- For the extruder the chimera options is harder to setup but less prone to problem. The cyclop is really temperamental when using the original I can’t be sure this clone will be better but it’s definitely less reliable

- That gift of a free nozzle can go to the bin straight away most clone are usually really badly machine causing huge amount of stringing so if you want to cheap get them from this shop instead

- They seems to have cheap out on the y axis by using 8mm smooth rod and at that length that start to be a bit bouncy

- No pictures of the extruder but I suspect they are using something similar to this and perso I think this is a crap direct extruder when combined with a bowden (bowden is the configuration when the motor pushing the filament is away from the carriage that carry the hotend)

-

-

Second link this architecture is the closest from the ultimaker or the makerbot. Perso I’m bias toward that architecture because I think out of the 3 it will be the more stable

- For the extruder and hotend read the things above

- bad things I can see is the acrylic uses for the carriage and especially for the extruder but those can most likely be replaced easily

-

-

Third link is a delta configuration

- Things to be aware is that Delta printer are the hardest to get right when you assemble them and subsequently the calibration will be directly impacted if the assembly is not right. Unless it’s an expensive delta printer the cheap option are only good for printing pokemon and vases or organic shape. Printing precise, reliable and reproducible parts is the hardest.

-

Alternative options:

- Geetech A10 : it as a bit smaller build platform but on overall the hardware seems better

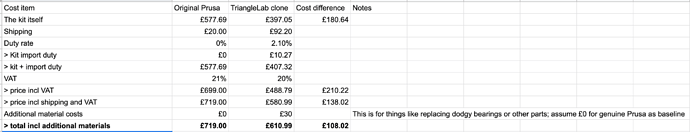

- Prusa I3 Mk3S This is probably the best options as the base machine and community support will be the best out there. There is a few hoop to jump through as you need to find that missing brass nuts but thinking about it you could mod that part to receive a plain narrow M8 nuts instead. (on the shop front FYSETC as good feedback from what I could read online)

I hope this help you a bit, feel free to ask any other question or let me know if you want to drop by for a chat. I’m usually in the space on Tuesday.

Have a great day.

ps : thx Dermot for the kudo