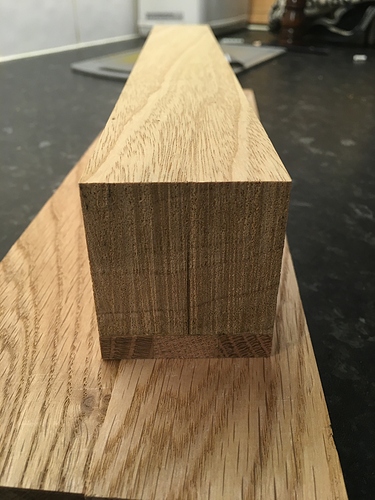

This is my latest project so far and is the only thing I can do until I have access to sufficient timber for my next projects.

I am making a Krenov style plane just for shooting and jointing. I have a 1 3/4 inch Hock blade and chip breaker.

I hit a stumbling block straight after sizing the Iroko main body. Every combination of the wood available meant the grain direction was wrong. I searched through every scrap I owned. About three hours of head scratching and measuring later I found literally the only way to solve the size and grain orientation problem. It’s not a conventional way to orient the grain but I am sure it’s going to work and shrinkage over time should give me concavity across the sole which is easily dealt with. Just gotta wait now until my drill guide arrives then I can make accurate holes for the cross pin. I am going to post some photos when I get done. I can’t wait to have a task specific plane for shooting. Perfect 90 s…zero lateral adjustment, beautiful. Simple carefully crafted tools give me accurate lifetime results. I have saved about 150 pounds as lie Nielsen and Veritas are the only people on earth who can accurately grind a plane side!

Lockdown project

The Hock blade is a full 5 mm thick at the edge. Plenty of reference for hand sharpening. The mass also helps eliminate chatter in my opinion. It’s a bargain I think at 50 pounds.

Looks great! I think we definitely need you to do a plane (types/sharpening/setup/adjustment) workshop when lockdown is over

The last two pieces. I made two cross pins,apparently it’s easy to mess them up. I halved the angle on the wedge as I tried 9 degree wedges before and they were impossible to lock, decreasing the angle solved the issue. Krenov himself didn’t use 9 degrees. Thplpimage|375x500

I successfully whittled the ten mm cylinders on each end of the cross pin and I got an incredibly accurate result. I didn’t need the spare. Now I am in need of a drill guide which has a bushing for a ten mm drill bit. I wonder does anyone have one I might borrow?

I got the plane together. I did it slightly differently than if I had a drill press. As I had to use a homemade drill guide I could only guarantee 95 percent accuracy. So I worked out the position of the cross pin and then glued the back part of the plane to one side. Then I attached the front block and then I offered up the other side until I was sure of the cross pin alignment ( I had already drilled the cross pin holes in both sides). When I was happy with the cross pin I pegged the side with dowels took it apart and glued it up. It’s all looking good.

Looking very sharp!

I just trued the side after letting it sit with the blade and wedge fitted. The angles from side to sole are very accurate already.

I got to buy a Shinto saw file for profiling the wedge. If you haven’t tried one, I can tell you they are really effective and the fine cut side leaves a very good surface. This tool will get a lot of use and is cheaper than an equivalent quality rasp. Available on Amazon for just twenty pounds with free postage at the moment. Look for the “ L” prefix denoting large.

I have just taken the first shavings. I just have the shaping to do now. Looks like it’s going to do the job.

Here is the finished plane. It’s only 12 inches long which may seem small for a plane specifically made to shoot accurately but, it’s not necessary to have a long plane. I am really happy with the result. It’s accurate and functional and if it wasn’t it would be in the bin. All hand tools and scrap wood.

I just thought I would do one final update. I have trued the plane twice and it seems to have settled down now. The wedge is always going to have some effect long term on the plane body and it’s wood so it will need truing occasionally. I made a new shooting board ( I can shoot a two foot length) it’s super accurate. Perfect 90 with the blade set true to the sole which is what I wanted. I am going to tap the sides to accept a fence so I can joint perfect 90s with little cognitive input. That’s another 50 pounds I won’t have to spend on a Veritas universal fence.

I am looking forward to your plane making workshop  which you will hopefully be doing!

which you will hopefully be doing!

How do you true a plane?

You flatten the sole and in the case of the plane I made, you then adjust the side until it is a perfect 90 degrees to the sole. You can then use the plane on the shooting board to achieve perfectly accurate edges and ends.