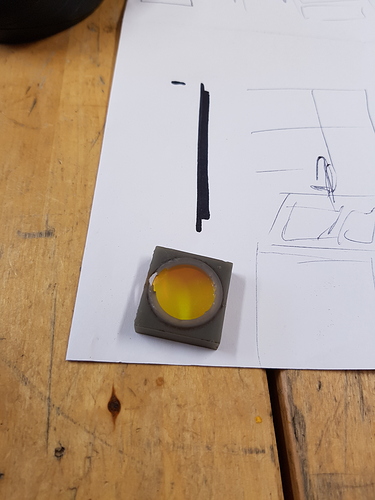

I found the laser lens a bit worse for wear this morning, some of the plastic holder has melted and stained a bit of the lens. I’ve tried cleaning up as best as I could and the centre of the lens is pretty unblemished, but the lens can quite easily fall out of holder when cleaning.

Any thoughts?

Laser lens

This was reported, @petra and I were going to assess the damage when we look at the machine tonorrow night…

Will put a plan into action for a replacement.

Why is the lens holder still plastic, isn’t it worth throwing some money at having a metal one sintered ? How many lenses have to break because someone forgot to tighten it up and the plastic melted before this is addressed?

If you recall, our original trotec lens in its metal holder got destroyed the same way… the only difference is that the metal holder would probably survive the error. I have got a quote for getting a one off metal holder made and If the consensus is a metal holder so be it?

Thoughts?

Maybe I am confused/wrong but I recall the laser cutter surviving the lens falling out with the metal holder because my understanding was that the plastic lens holder melts when the laser beam hits it and then causes the lens to crack due to heat, where the metal holder is not able to melt?

The metal holder we had originally had the lens glued in place, when someone forgot to tighten the locking ring, the lens shited and the laser beam destroyed the lens. We tried to place a replacement lens in the holder but the aperture was the wrong size for the lens. We then replace the holder with plastic ones. Lately the lenses have been destroyed in the same way, people forgetting to tighten the locking ring. A metal holder will mean the survival of the holder when such an error occurs but may not save the lens within it…

What about some kind of catch to ensure it can’t slide out if left unscrewed. Will still need to be screwed in to keep it focused but would eliminate the sliding out issue. @Will and I chatted about this issue a while back and it shouldn’t be too hard to make.

A small magnet drilled into the back of the lens holder would attract to the metal bracket that holds the lens holder.

I like that idea, really elegant - is the metal bracket not aluminium though? (though we could add a second magnet)

Theres a galvanised steel bracket at the back of that as I recall which is what the timing belt attaches to.

Ah yeah I think you’re right, good shout.

I have some small cylindrical magnets - 3mm diameter - that may be what you need. If you think they will be useful let me know and I’ll drop a few off.

how about people just take care when they use the machine. I am really against drilling and fixing magnets into the laser head.

Interesting ideas here…

But as @Jonathan said: let’s just take care of it from now on

Also it was good to hear that the member who had the mishap owned up immediately – we all make mistakes!

Hi Everyone,

I came into your space last week when I was desperate to laser some plywood jigs for an urgent project. You guys were enormously helpful and let me cut a couple of bits. Thanks so so much. It genuinely moved me that people could be so nice to a complete stranger. Unfortunately I didn’t have any cash and so didn’t pay for the material i used, so i’d like to rectify that and on top of that, wanted to see if i could offer any help to you.

So, I’ve ordered 12 off 5mm clear acrylic 730 x 430mm to be delivered to you as a replacement for the 4 x plywood pieces I used. hope that’s ok. Is there anything I need to say to the driver about making the delivery? opening times? contact number? etc

Re me helping you: I have a fair amount of experience of designing things, particularly in acrylic, and some good contacts in the industry and would be happy to help anyone looking to produce products. Judging by the various threads in this forum, it seems like you already have a deep well of knowledge in your group, but I’m happy to add my name to the list.

Also, when talking with Petra about the Laser, (I have an antique Trotec laser in my shed at home) she mentioned that you have an alternative supplier for lenses that were significantly cheaper than Trotec themselves, and that you had made your own lens carriers. Do you think you could let me know the details of this supplier as I have now realised that all of the problems i have with my Laser are caused by the hideous state of my lens and mirror - see images attached.

Thanks again,

Fred

If it an error occurs more than once then it’s systemic. You can’t resolve those types of problems just with education when there are always new members. For example I’ve done my induction recently, I’ve used the machine for the first time last week and I had 0 knowledge of the possibility of this problem happening.

Hi Fred,

Thats amazing,thanks for the perspex! Perhaps only “if not in, leave with mot or canopy” to be delivered to lasertechs.

Nice to see your trotec, what sort o extraction you said you’ve got?

Also…you need to clean your mirror,man!