Nice! I can’t see the picture tho! Try readding with the upload button…

Headphone Stand

Cool, yeah looks longer in the ad… but thats ok, plenty to work with!

Paul - ‘Forward Metals’ might have brass strip close to the dimensions you were thinking of, and they just cut to length - for example: 2" x 1/8" x 500mm (apols for mixed units!) comes up on their website at £14.77 + VAT. Loads of other sizes.

Haven’t used them for ages, so don’t recall what the postage was.

(I’m new here: are we allowed to post links in discourse? Apologies if not…)

Perhaps you could cut some wooden formers to bend it around? Might be a bit of trial and error involved

EDIT: Oops… just noticed that you’d already bought some material…

Yes - no worries, thanks for sharing! Turns out these things were smaller than they appeared so he may need more materials!

You gonna need a dividing table for that pattern. I found the files for 3d printing a rotary table, and dividing plates(we can lasercut the plates too), we just need to sheperd the printers for a day or two until they print it out. mount it on a big wedge on a plank and put it under the bandsaw) We can make some support for bending out of scrap wood and pipes laying around, and I have a couple polished hammers I can chuck in my backpack when your’re forming it. ( plus we have a set of sheetworking hammers too) I would use the claws to hold the headphone so we just need to bend that round bar ( is it solid?) and cut a thread on it for mounting. walnut is hard enough to cut a thread in it.

@Gergo_Dala I’ve got a few ideas a well, would love a chat with you about it and will definitely require your help. I’ll bring the pieces in next time I’m in

Another idea would be to cnc the base profile and a half angle jig and still side cut the flats. No 3D contouring on the cnc or dividing head required.

Thats you’re cup of tee, I’m painfully analogue in fabrication sometimes  btw can we drill a set of concentric holes in mild steel on the cnc?

btw can we drill a set of concentric holes in mild steel on the cnc?

No steel unfortunately and both machines are relatively high speed/low torque so are happier milling rather than drilling (with some caveats for small drills).

Thatbwad theboriginal plan, layout on paper, double sided tape, punch and drill a lot😆

I’ve done some CNC marking if that interests you

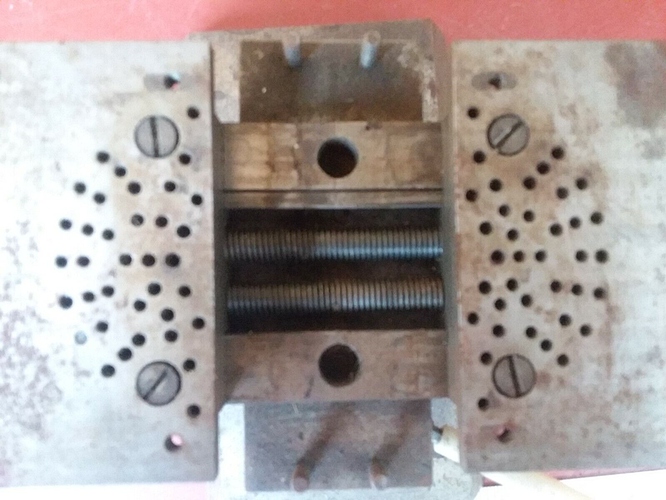

That would be great! I’m planning to make a pin vice like this ( just with a left-right threded locking bar to keep the weight down.

Sorry for offing the headphone stand I’ll be down next weekend

Oof. That looks like a DRO job to me…

How precise are you going? Do the holes have to be reamed?

I am thinking about building an automatic center punch holder for the big CNC  Need to do some force measurements first

Need to do some force measurements first

It’s to hold random shaped stuff with pins so hand and divider accuracy is enough, they made these the same way in the back of the workshop, thats why the 2 screw solution. I purchased an m8 left handed tap and die so it’ll work like the ball